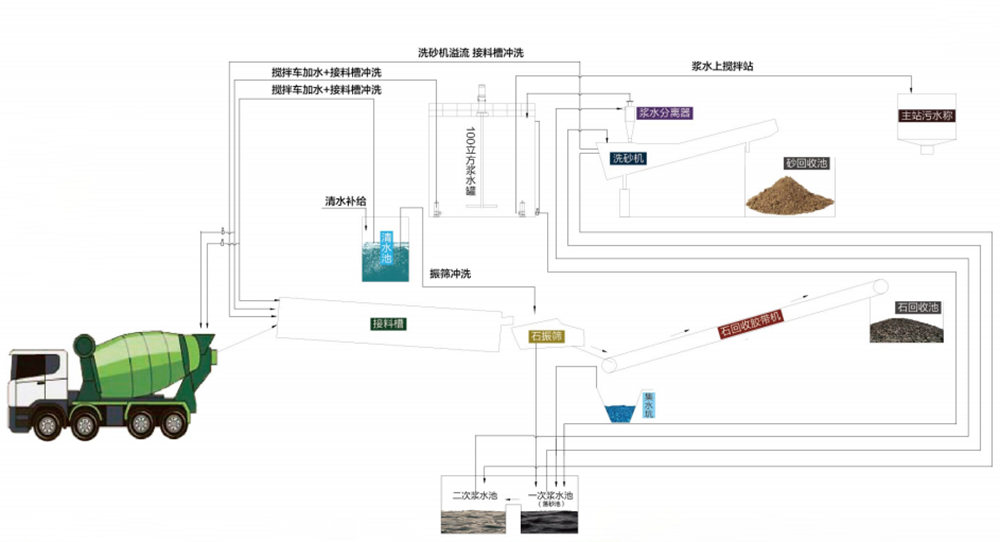

Ready-mixed concrete zero-emission recovery equipment

Ready-mixed concrete zero-emission recovery equipment - sand and gravel separation system

This product is suitable for the fast recovery and processing of concrete surplus in multiple grades produced by various types of mixing plants. Decompose the concrete surplus material into 5 mm or more stone aggregate, 5 mm or less sand aggregate, slurry water containing powder and admixture. The decomposed aggregate and slurry water can be reused, and no surplus waste will be generated during the use process. Separation and transportation of components in recycled concrete: aggregate separation - vibrating screen screening; stone aggregate conveying - belt conveyor; sand and aggregate separation conveying – spiral sand washer; fine sand separation - special fine sand separator.

Farewell to traditional technology, ultra-fine separation effect, 100% resource recycling, zero pollution

This product is suitable for the fast recovery and processing of concrete surplus in multiple grades produced by various types of mixing plants.

Decompose the concrete surplus material into 5 mm or more stone aggregate, 5 mm or less sand aggregate, slurry water containing powder and admixture.

The decomposed aggregate and slurry water can be reused, and no surplus waste will be generated during the use process.

Separation and transportation of components in recycled concrete: aggregate separation - vibrating screen screening;

Stone aggregate conveying - belt conveyor; sand and aggregate separation conveying – spiral sand washer; slurry water separation - special slurry water separator.

Upgraded concrete mixing plant: Recovery and recycling zero-emission system - slurry water separation system

This product is a slurry-water separation system independently developed by our company based on the wet concrete recycling sand and gravel separation system to meet the market demand and the new high requirements of environmental protection in the industry. The slurry in the slurry water is further separated from the clear water by a special horizontal centrifugal device, and the slurry is measured and directly involved in the concrete production, so as to realize the automatic recycling of the slurry and sewage. It solves the problems such as large workload of wet concrete, high slurry water concentration, unstable slurry water concentration, low sewage usage and utilization rate during the recovery and recycling of wet concrete, making it difficult to completely realize the zero discharge of sewage. The system product design breaks through the bottleneck of the traditional concept, is highly reliable and applicable to the in-depth upgrading of treatment and sewage recovery systems in the concrete production industry for environment protection, can completely achieve zero pollution, zero emissions.

Technical Characteristics

1. With high speed, a special centrifugal device is adopted to quickly and automatically separate the large amount of slurry water generated in the wet concrete recovery process into slurry and clean water.

2. High efficiency, clear and pure water after separation, which can be widely used in concrete production. The slurry after separation is automatically measured by scientific proportioning to participate in concrete production. Active ingredients in the slurry can also effectively improve the concrete performance and the concrete strength.

3. The process is simple, and the system does not need to be equipped with a pressure filter, thus saving input.

4. The operation cost is low, and there is no loss of filter cloth on filter presses.

5. The system features a small footprint and low energy consumption.

Automatic control system

Powerful mixer

Finished brick from autoclaved lime-sand brick production line